Tinsmith

Specialists in all things metal

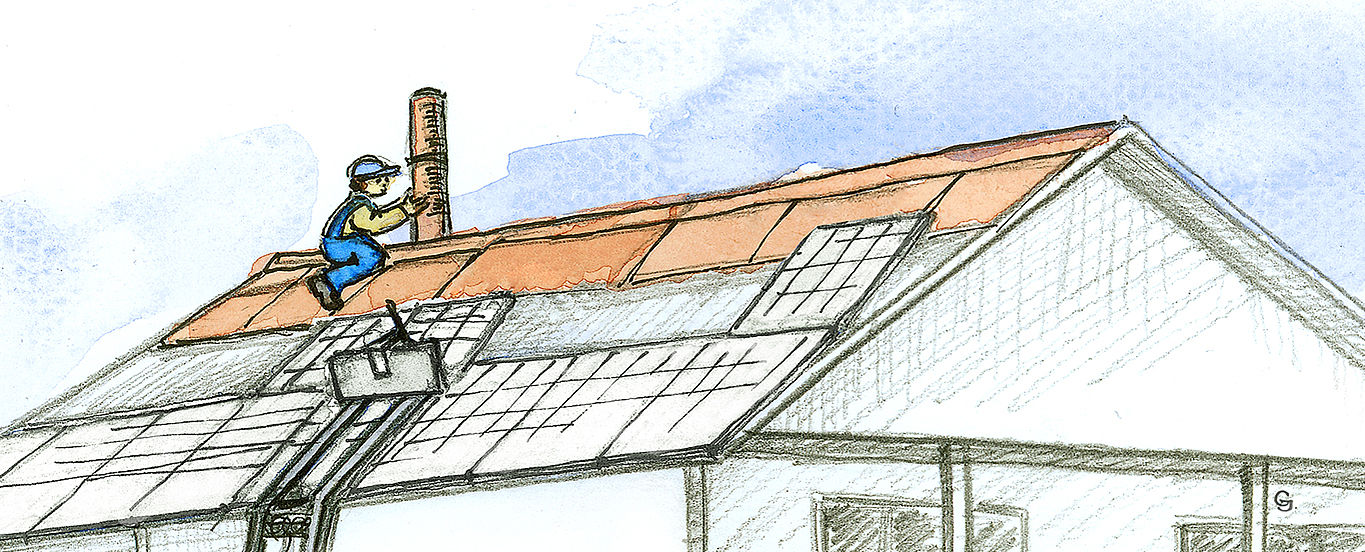

Sheet metal workers are the professionals when it comes to using metal sheets to make roofs and façades wind and rainproof. Customised production elements and the installation of rain gutters, snow guard systems, a new chimney or a dormer roof all form part of the comprehensive range of activities undertaken by sheet metal workers.

However, such sheet metal specialists not only work on private houses and on commercial buildings; they also work on church renovations and when they have finished their work on church roofs and spires in particular the shining roofs frequently attract attention.

Depending on the specific assignment, sheet metal workers use many different metals to bend and mould the sheet metal parts.

Be it for roofs or façades – GEDA has the appropriate height access technology

As well as the workshop, the sheet metal worker's place of work is clearly the roof or the façade. When it is time for the final assembly on the construction site the experts often arrive with bulky luggage that of course has first to be transported high in the sky to its point of use.

Sheet metal workers will find the right solutions for fast and safe height transportation in the extensive GEDA product range. Whether it is a question of metal elements for sealing the transition between roof and chimney, rain gutters or sheet metal slates for a wide range of roof and façade systems, all the relevant tools can be transported upwards safely with a GEDA lift.

From compact wire rope lifts through pure material lifts to transport platforms for personnel and materials, GEDA offers the entire bandwidth of practical height access solutions, which with their wide range of load carrying devices and accessory parts, can be adapted flexibly to the requirements of sheet metal workers.

Nor do cramped space conditions present a construction problem. The ease of assembly and their ease of use are additional plus points. Alongside time and cost savings, the use of a GEDA construction hoist also protects the health of employees since energy-sapping carrying of heavy, bulky metal parts all too often leads to back pain and therefore also to illness-induced absences.